Feb 2024 | New low flow valve type 7042 for very low flow rates and high-pressure applications

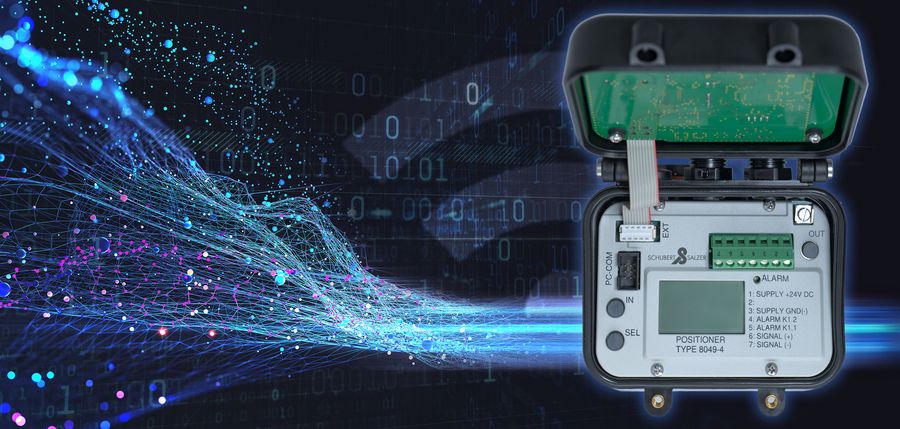

With minimum Kv values of 0.0027 to 1.7 and a nominal pressure of PN320, the new low flow valve type 7042 is ideal for the precise control of very small flow rates as well as in high-pressure applications. It can be used as a safe stop valve, especially for high pressures. The optionally integrated, digital positioner type 8049 is particularly easy to maintain thanks to its top-mounted installation. It is available with IO-Link, IIoT module and in an ATEX or FM version.

The low flow valve type 7042 has a valve body made of stainless steel barstock material, hardened valve spindles and a metallically sealing, replaceable seat seal made of hardened stainless steel or carbide to ensure maximum reliability and a long service life even in high-pressure applications. A special high-pressure packing ensures a high level of tightness, even with hydrogen, for example.