Pinch and Diaphragm valves

Versatile – resilient – straight.

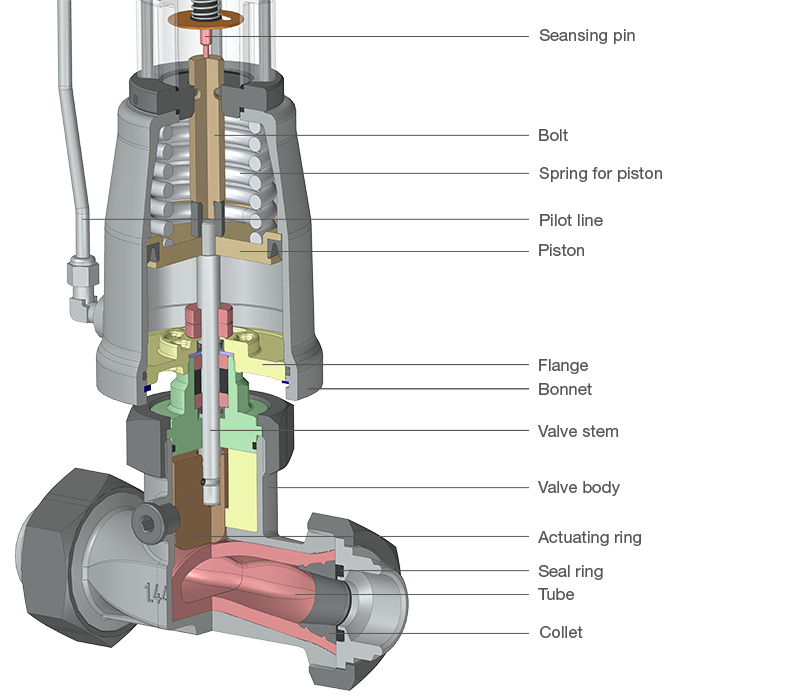

Design principle of pinch and diaphragm valves

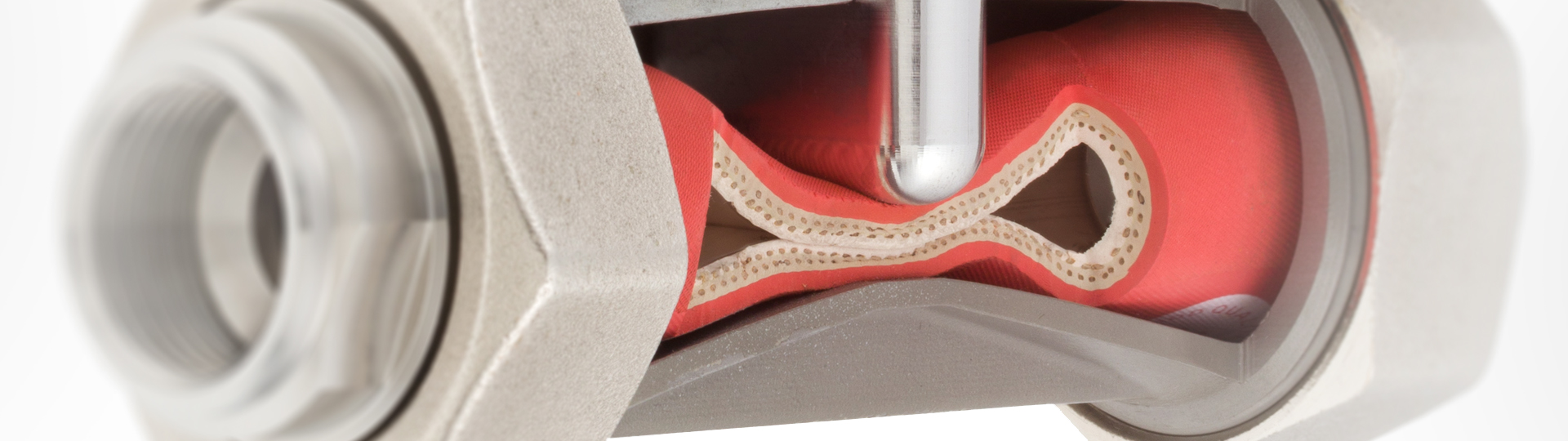

Schubert & Salzer pinch valves and diaphragm valves use the elasticity of high-performance polymers as a throttle. Pneumatic actuators compress the tubes fixed in the valve body or inserted endless tubes through specially designed pressure pieces. Due to the spring reset in the actuator and the operating fluids itself, the pinch valves and diaphragm valves move to the respective safety position or desired valve position.