Ball Sector Valves

The valve for abrasive and slurry on/off and control applications.

Our selection of ball sector valves

Our selection of ball sector valves

-

![[Translate to English:] [Translate to English:]](/fileadmin/user_upload/ControlSystems/Produkte/Typen/4040/Schubert_Salzer_Typ_4040.jpg)

Ball Sector Valves

To the products -

![[Translate to English:] [Translate to English:]](/fileadmin/user_upload/ControlSystems/Produkte/Typen/4080/Typ_4080.jpg)

Three-way Ball Sector Valves

To the products

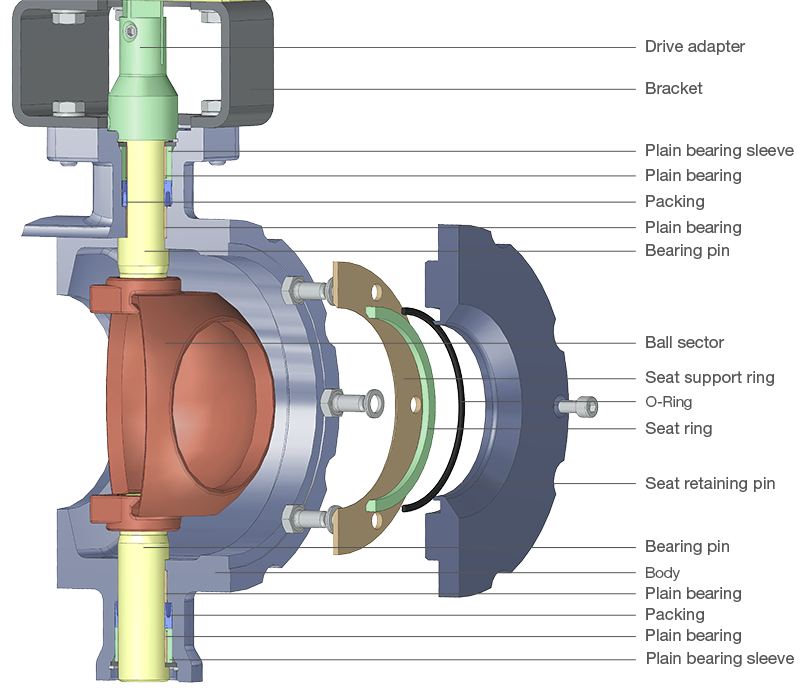

Design principle ball sector valves

The key element of these on/off and control valves is a ball sector that can rotate by 90° and is used as a flow control element. Even under the toughest operating conditions, the ball sector seals the media using a simple, replaceable seat ring in the body. One part of the ball sector serves to shut off the valve, and the other has a hole with a diameter that normally corresponds to about 80% of the nominal size of the valve. To avoid effects of thermal or mechanical stresses, the bearings and the shaft seal are mounted in swiveling bearing bushings in the body. The shaft is sealed using a self-adjusting PTFE packing with an integrated spring element that protects the bearing against media particles. Ball sector valves have centric bearings and stable trunnions. This allows the ball sector to maintain constant contact with the valve seat seal while it is rotating. Changes in the differential pressure do only have a minor influence on the constant actuation torque.

The advantages of ball sector valves

Minimal wear even with contaminated, abrasive and pasty media

Precise control over a large control range

Low actuation forces due to shaft journals with bearings

High KVS value

Robust and compact design

Long service life, low operating costs

Simple maintenance and repair

No flow deflection

No draining of paper stock due to elliptical flow geometry

Durable under extreme conditions

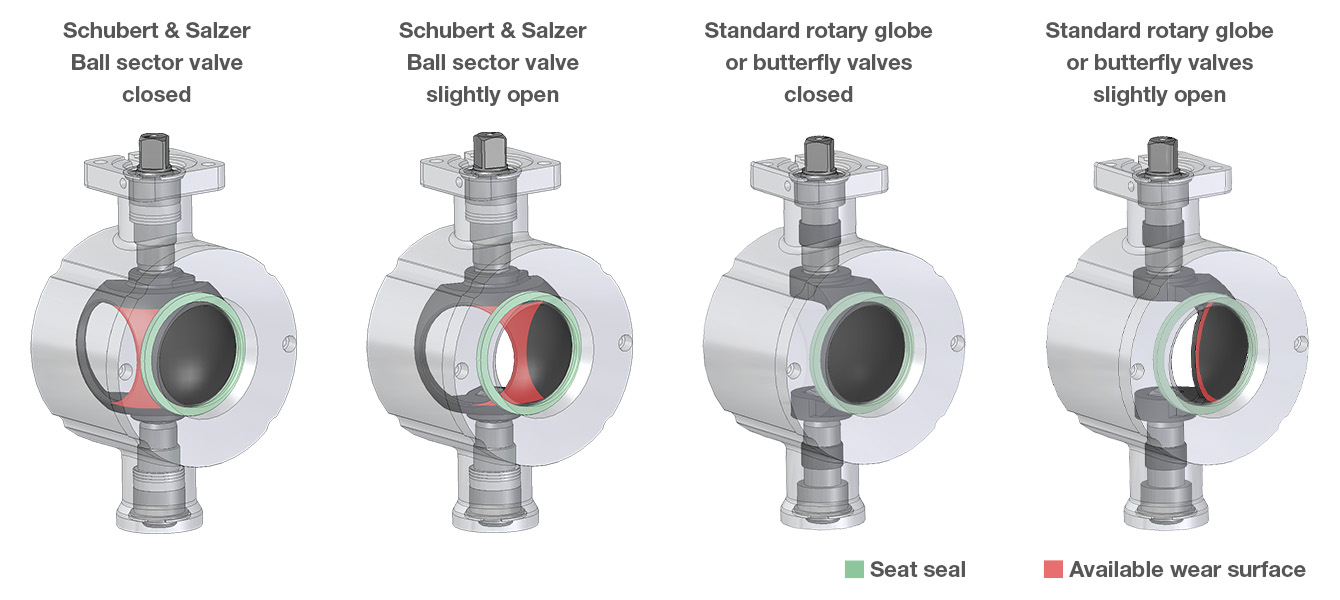

Wear caused by abrasive media starts at the control edge of the throttle. The sealing surface on the ball sectors is far away from the control edge of the ball sector and is not exposed to high flow velocities. Even heavy wear therefore leads to leaks much less frequently and later than with rotary globe valves. This beneficial sealing concept, combined with different materials and surface treatments for the valve seat, is the basis for long service life and reliable operation, particularly in applications with abrasive, highly viscous or fibrous media.

Excellent rangeability

Ball sector valves have a very high rangeability of 300:1 and therefore enable precise control over a wide control range. Combined with high-resolution actuators, the most demanding control tasks can thus be managed.

No clogging or draining with fibrous media

Ball sector valves have an elliptical flow opening, which means that even small flow rates of fibrous media (e.g. paper pulp) can be controlled without draining or clogging the valve.

Wear-resistant thanks to protected sealing surfaces

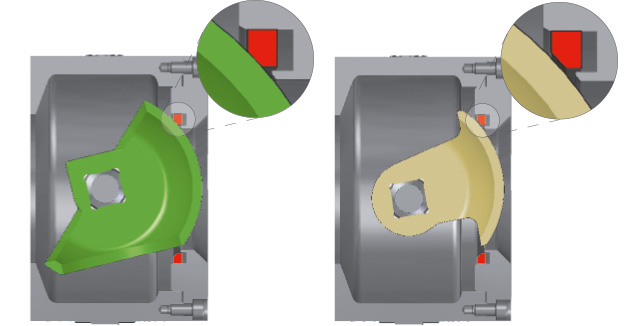

Due to their central bearing, the ball sectors maintain continuous contact with the seat seal during rotation. Contrary to eccentric standard rotary globe valves, the sealing surfaces of ball sector valves are therefore protected against the attack of abrasive media even in the open position. Furthermore, solids from the medium cannot get jammed between the ball sector and the seat ring and cause damage.

Unlike ball sector valves (left), rotary globe valves (right) lift off the seat seal when rotating. This often results in damage to the sealing surfaces of the rotary globe valves due to abrasion and jammed particles.

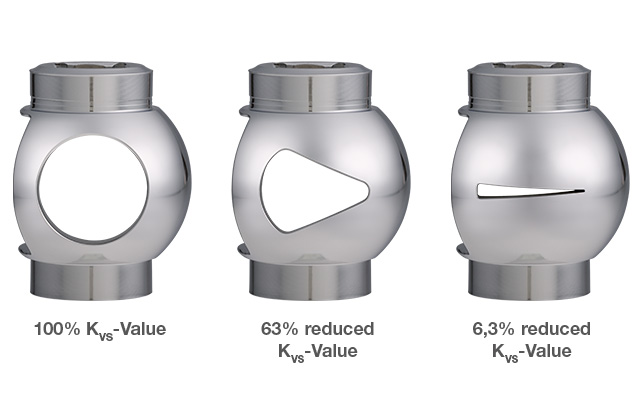

High and variable Kvs values

When open, ball sector valves allow the media flow to pass through almost the entire nominal pipe diameter. They therefore achieve very high Kvs values and do not deflect the flow.

Because of the different flow openings of the ball sectors, the Kvs value can be adjusted precisely to the requirements of the respective application.