Sanitary valves

Ultra-clean – precise – aseptic.

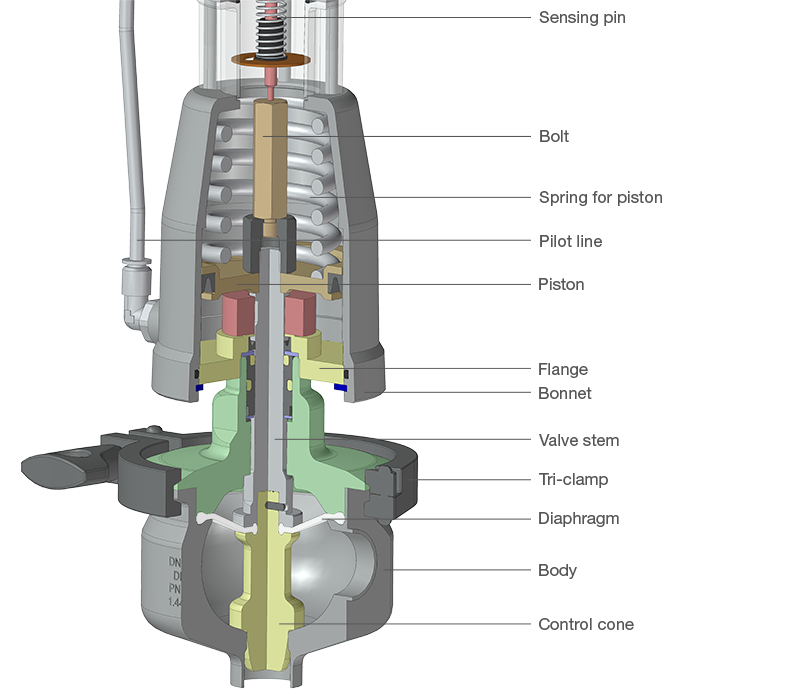

Design principle sanitary valves

The demand for absolute cleanability in pharmaceutical and food processes depends directly on the flow conditions. In a nutshell, this means: the higher the flow velocity, the higher the wall shear stress on the surfaces in contact with the fluid and thus the greater the cleaning effect. A special EPDM diaphragm with a PTFE film coated on the process side separates the process chamber from the valve actuator.

The valve body is manufactured from pore-free stainless steel 1.4435 barstock material, finely turned or electropolished with roughness depths from Ra < 0.6 µm to Ra < 0.25 µm. The control plugs made of PEEK are FDA-compliant and meet the requirements of the USP Class VI, of the EU regulation 1935/2004 and the new plastics regulation 10/2011.

For inspections, or if a repair should be necessary, the aseptic right angle valve can be opened easily and quickly thanks to a clamp connection between valve and actuator. This valve series is characterized by compact pneumatic piston and diaphragm actuators combined with the proven digital Schubert & Salzer TopMounted positioner (optionally made entirely of stainless steel).