Segmented disc valves

Robust, durable, backpressure tight and highly precise.

Segmented disc valves by Schubert & Salzer

Segmented disc valves by Schubert & Salzer offer a perfect and variable control with high precision over a wide flow range. Due to the robust design and the bi-directional flow capability, segmented disc valves are suitable for fluids as well as vapours, even if these are contaminated by particles. The range of applications includes areas such as building materials, chemical and power plants, pipelines, water supply and disposal, as well as shipbuilding. Especially when used on autoclaves, e.g. for the manufacture of limestone bricks and aerated concrete, they are characterised by long service lives and reliable operation.

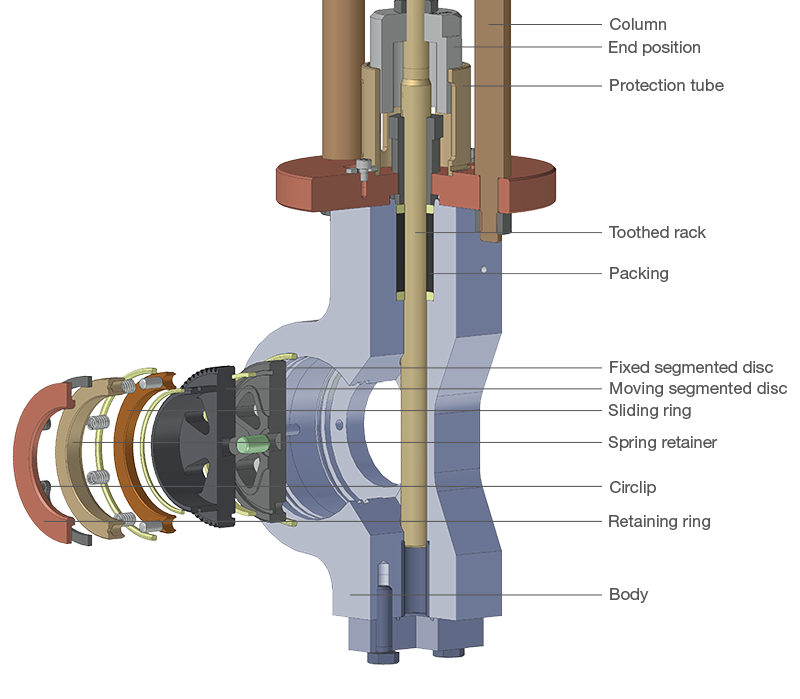

Design principle of segmented disc valves

Segmented disc valves work on a very simple but effective principle. The central throttle is formed by two segmented discs that slide on top of each other and seal each other – one of them fixed, the other movable. The geometry of the fixed segmented disc determines the valve’s flow capacity and characteristic. The moving disc is rotated on its fixed counterpart in such a way that the segmented flow openings continuously change. Both discs are constantly pressed against each other by a spring assembly. This means that the flow direction is variable and the valve can be fitted in any position. The movable disc is rotated on its fixed counterpart by a tangentially engaging push rod, so that the size of the flow apertures changes continuously.